Over the years the folks at Superior Threads have worked with thousands of customers, educators, and innovators in the quilting industry. Every year they learn more about the quilting and sewing world.

Here is Part 2 of their most frequently asked questions, along with the answers, from 2015:

#6 Q: Do you have piecing thread?

MasterPiece will help you create perfectly pieced seams without bulk or lint. Your machine will stay very clean. Designed with superstar quilter Alex Anderson, MasterPiece is the best #50 cotton piecing thread available. MasterPiece is available in 75 colors and is also recommended for appliqué and as a the bobbin thread.

MasterPiece will help you create perfectly pieced seams without bulk or lint. Your machine will stay very clean. Designed with superstar quilter Alex Anderson, MasterPiece is the best #50 cotton piecing thread available. MasterPiece is available in 75 colors and is also recommended for appliqué and as a the bobbin thread.

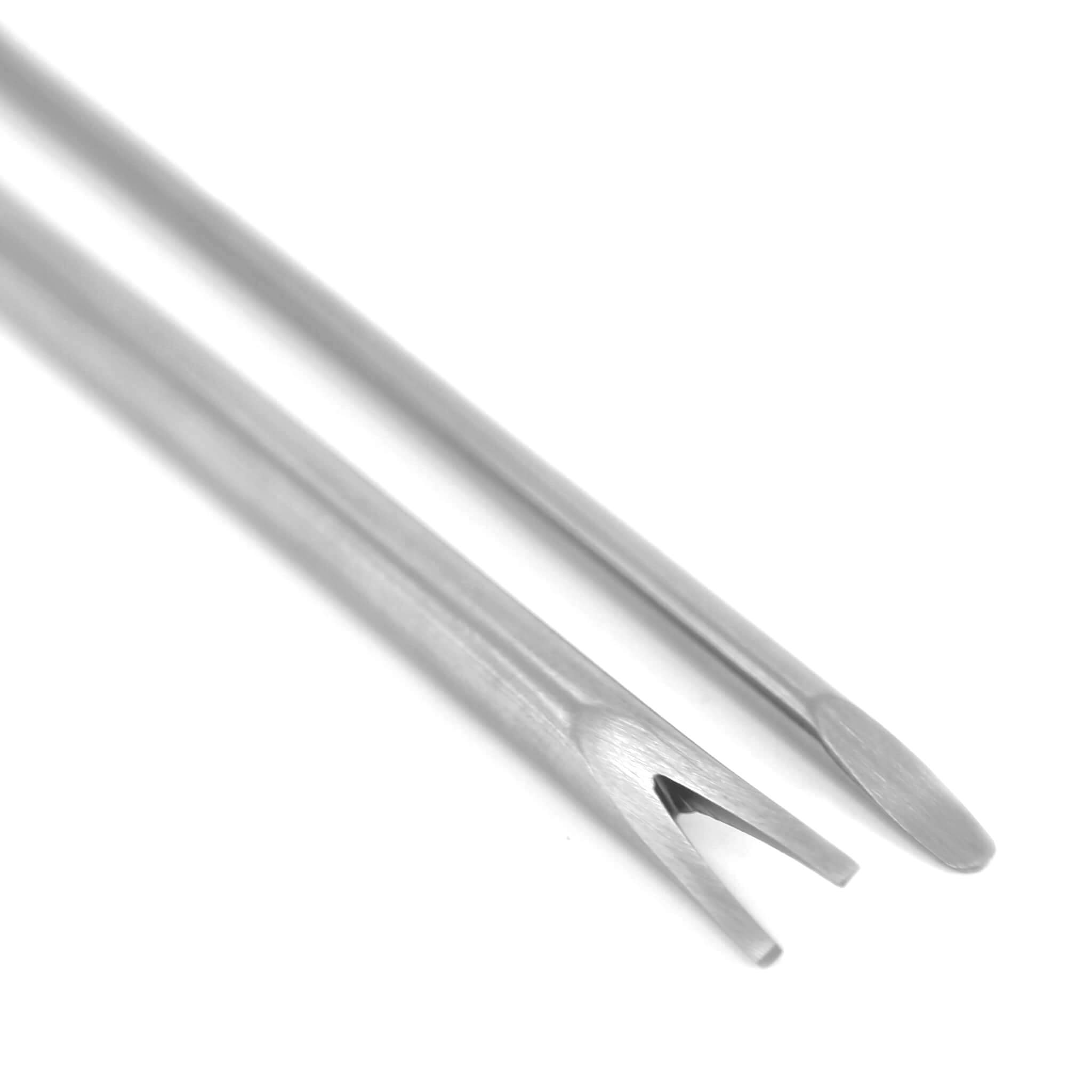

#7 Q: How can I tell if the problems are with the thread or the machine?

Check out our Troubleshooting Guide. It will show you how to determine if the problem is with the thread, the needle, the tension, or the machine. Become an expert by mastering each step of this Troubleshooting Guide. This popular guide is also found in our Product Catalog.

Check out our Troubleshooting Guide. It will show you how to determine if the problem is with the thread, the needle, the tension, or the machine. Become an expert by mastering each step of this Troubleshooting Guide. This popular guide is also found in our Product Catalog.

#8 Q: My machine has automatic tension. Do I still need to adjust the tension settings?

This is a big YES! Newer machines come preset with faster speeds and tighter top and bobbin tensions designed to sew with a 50 or 60 wt. polyester thread. Factory preset tension (usually set at 5.0) is too tight for most quilting and embroidery applications. Automatic tension does not know if you are using a very delicate thread, sensitive thread, or heavy thread. It does not know if you are using cotton or poly or metallic or monofilament thread. Learn to override the automatic tension setting and adjust it (usually loosen) to the point where you get the perfect stitch. Knowing how to adjust the top tension will open up your thread choices so you can use any quality thread without frustration. On most machines, we set the top tension between 2.0 and 3.5 (see Home Machine Thread Reference Guide). When using metallic thread, we go all the way down to 1.0. The tension concept is explained on our Tension Tug-O-War diagram.

This is a big YES! Newer machines come preset with faster speeds and tighter top and bobbin tensions designed to sew with a 50 or 60 wt. polyester thread. Factory preset tension (usually set at 5.0) is too tight for most quilting and embroidery applications. Automatic tension does not know if you are using a very delicate thread, sensitive thread, or heavy thread. It does not know if you are using cotton or poly or metallic or monofilament thread. Learn to override the automatic tension setting and adjust it (usually loosen) to the point where you get the perfect stitch. Knowing how to adjust the top tension will open up your thread choices so you can use any quality thread without frustration. On most machines, we set the top tension between 2.0 and 3.5 (see Home Machine Thread Reference Guide). When using metallic thread, we go all the way down to 1.0. The tension concept is explained on our Tension Tug-O-War diagram.

#9 Q: Why does it matter how I position the spool of thread on the machine?

How the thread gets from the spool or cone to your machine is important. Spools of thread that are stack wound (or straight wound or parallel wound) are made to unwind from the side of the spool (as the spool rotates) and not over the end or top of the spool. Remember, straight wind on, straight wind off. Cones, on the other hand, are always meant to unwind over the top of the cone. Most machines have a vertical spool pin to hold the spool of thread. Position the spool on the vertical pin so the thread will unwind straight from the side of the spool, with the spool rotating. Straight-wound spools should not be placed on the horizontal pin that unwinds the thread over the end of the spool, causing twisting. Our video on the Thread Delivery shows this explanation perfectly.

How the thread gets from the spool or cone to your machine is important. Spools of thread that are stack wound (or straight wound or parallel wound) are made to unwind from the side of the spool (as the spool rotates) and not over the end or top of the spool. Remember, straight wind on, straight wind off. Cones, on the other hand, are always meant to unwind over the top of the cone. Most machines have a vertical spool pin to hold the spool of thread. Position the spool on the vertical pin so the thread will unwind straight from the side of the spool, with the spool rotating. Straight-wound spools should not be placed on the horizontal pin that unwinds the thread over the end of the spool, causing twisting. Our video on the Thread Delivery shows this explanation perfectly.

If your machine does not have a vertical pin, Superior has a Thread Holder that provides correct thread delivery for both spools and cones. It is easily portable and can be used on any machine.

#10 Q: Will using prewound bobbins void the warranty on my machine?

This is a common question and unfortunately believed by many because they were told this by their machine dealer. I have never seen this written in a manual or on a warranty card of any brand of machine. To confirm this further, I contacted the headquarters of several machine companies. Their collective answer was unanimously: "Prewound bobbins will NOT void the machine warranty. There is no problem using quality prewound bobbins." If your machine model is compatible with prewound bobbins, choose quality bobbins and enjoy the convenience.

This is a common question and unfortunately believed by many because they were told this by their machine dealer. I have never seen this written in a manual or on a warranty card of any brand of machine. To confirm this further, I contacted the headquarters of several machine companies. Their collective answer was unanimously: "Prewound bobbins will NOT void the machine warranty. There is no problem using quality prewound bobbins." If your machine model is compatible with prewound bobbins, choose quality bobbins and enjoy the convenience.

.jpg)

RSS feed for comments to this post