Why would a smooth polyester thread shred and break when sewing, while an all cotton thread will not?

Is the problem with the:

- Needle?

- Thread?

- Machine?

Looks like it could be the machine.

Here's the answer from Superior Threads:

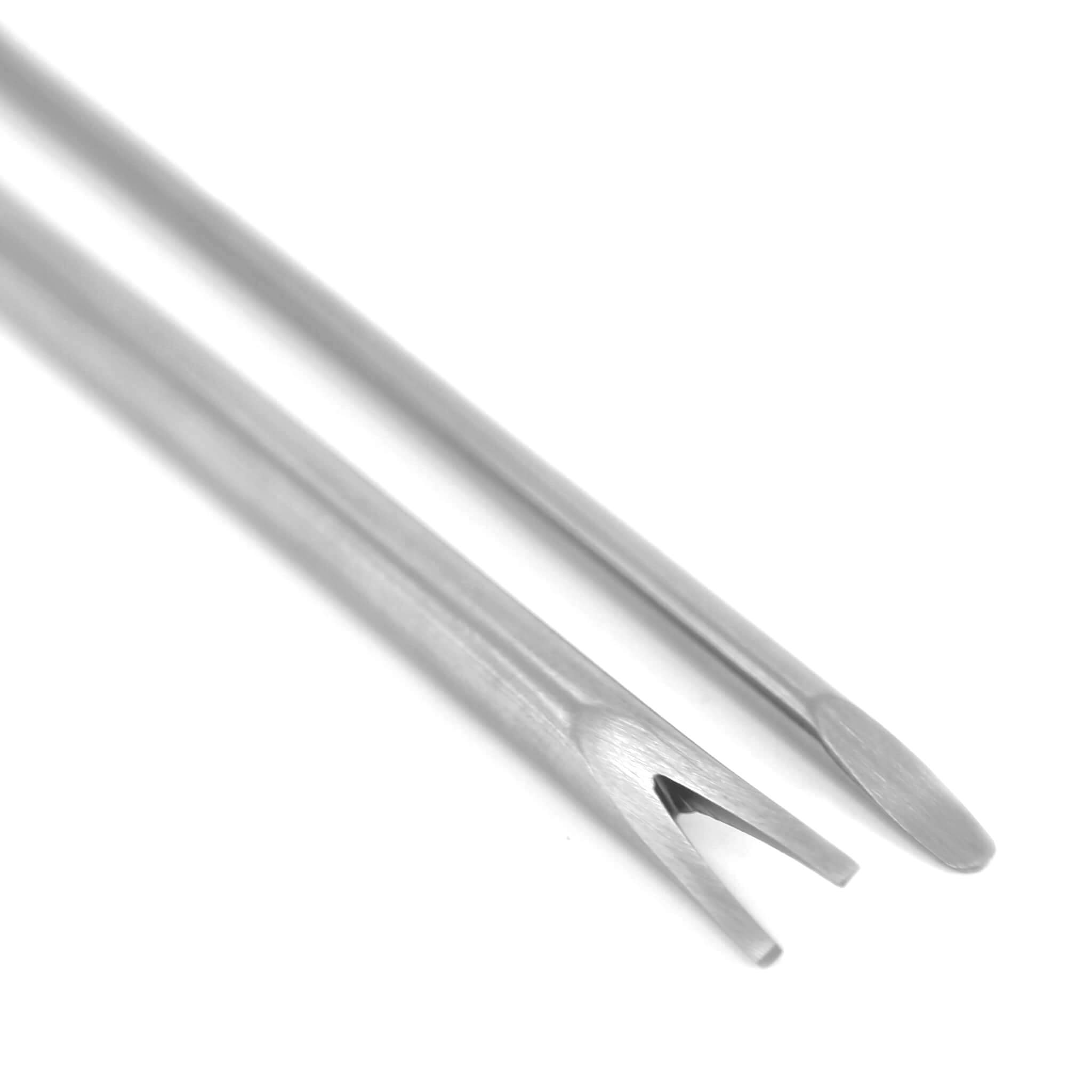

Thread travels from the spool or cone, through thread guides, the tension discs, more thread guides, the take up lever, and the needle. Over time, small grooves may be worn, or rough spots develop, along the thread path. If a cotton thread hits a rough spot or burr, it snags a piece of the thread (creating lint), and the thread keeps moving along without any problems. However, if a smooth multi-filament polyester thread hits a rough spot or burr, the rough spot snags the thread. There is no lint or spun piece of thread to give, so the thread is damaged and shreds or breaks. The solution is to make sure there are no rough spots along the thread path.

.jpg)