There is a lot of good lessons in the Superior Threads newsletter. Be sure to sign up for more info. Here is a very good article from the last newsletter.

EDUCATION: It's a Tug-of-war

I don't mean to boast, but . . . I have done something that very few people have ever done. I have read a sewing machine Owner's Manual from cover to cover. While reading the chapter on tension I had an Ah hah! moment. It was such an awakening, I still remember it today although it was six years ago. I was reading page 51 about tension. The manual stated that the top tension setting was factory preset to sew with a 50 or 60 wt. polyester thread. This particular machine was the top of the line machine at that time. Although it offered everything including fancy stitches, embroidery capability, features for excellent piecing and quilting, I realized then that it was designed first and foremost as a sewing machine, not as a quilting or embroidery machine. This explains why the top tension settings were factory preset to sew with a 50 or 60 wt. polyester thread. That is sewing thread, not the usual quilting or embroidery thre ad. Sewing machines are made around the world for the world. The world sews. We quilt.

This realization led to greater curiosity and subsequent research into sewing machine tension. One of the best lessons I heard on this topic was from Libby Lehman. Think of the top and bottom thread as having a tug of war.

If the threads are identical and you are sewing on a single layer of fabric and the tension settings are perfect so both sides have equal strength, the result will be a draw. The sewing should therefore produce perfectly even stitches with no top thread showing underneath and no bobbin thread showing on top. However, in the real world, the teams are rarely equal. One team will be stronger or bigger or faster or smoother than the other. We sometimes use decorative or sensitive threads on top. We often use different fibers for the top and bottom threads. We also add stabilizer or batting. Sometimes we might use a cotton bobbin thread and other times we use a polyester bobbin thread. All these factors make it necessary to adjust the tension for each project. By adjusting the top tension either up or down, we are able to add or take away strength on the top thread team to equalize the tug of war battle. Following is a list of things that affect stitch results:

1. Batting. This adds drag on the top thread. Cotton batting tends to grab the thread more than poly batting, adding more friction on the thread.

2. Fabric type. Dense fabric puts more stress on the thread.

3. Top thread thickness and type. Metallic is less flexible than cotton or poly. Poly is usually stronger than cotton or rayon.

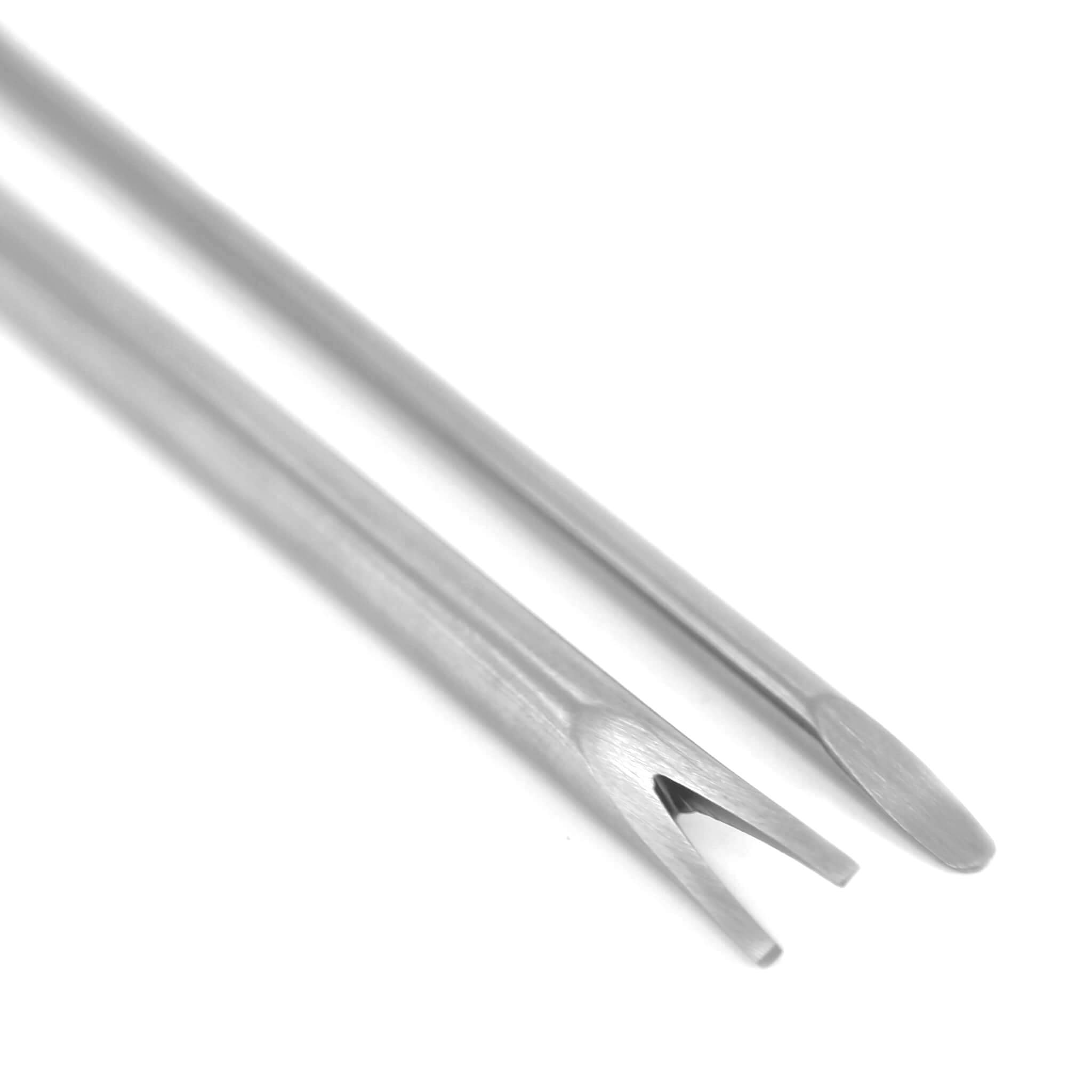

4. Bobbin thread type. Cotton bobbin thread tends to grab more than a smooth filament polyester. Sometimes grabbing is preferred (when piecing) and sometimes it causes problems (with metallic thread). A smooth filament poly thread (not spun poly) in the bobbin will work better with metallic and other sensitive threads because its smooth finish acts almost like a lubricant, sliding nicely with the thread.

Conclusion: We cannot rely on automatic tension settings. There are too many variables. As illustrated in the above diagram, if the top thread is showing underneath, either the top tension is too lose or the bobbin tension is too tight. Either tighten the top or loosen the bobbin. If the bobbin thread is poking through the top, either the top is too tight or the bobbin is too loose. Loosen the top or tighten the bobbin. When making adjustments, begin with the top tension.

Full page printable image of above diagram

.jpg)